This wire is commonly used in aircraft suspension, robotic components, high-strength cables, and medical applications where flexibility and resistance to wear are essential.

Our Expertise:

We manufacture custom Nitinol twisted wires designed for specific industrial applications.

Key Features:

✔ Excellent energy absorption properties

✔ High flexibility and durability

✔ Customizable wire diameters and strand configurations

Custom Product Development:

🔹 Custom wire diameter, length & mechanical properties

🔹 Prototype Development & Mass Production

Applications:

🔹 Aerospace & Defense: Aircraft vibration dampening systems, spacecraft components

🔹 Medical: Orthopedic devices, catheter reinforcement

🔹 Railway & Automotive: Shock-absorbing suspension cables

Rope Wire Diameter Tolerance

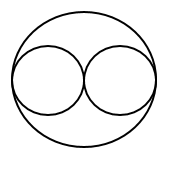

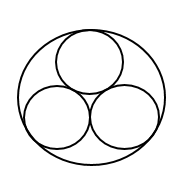

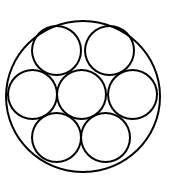

| Structure | Diameter Range (mm) | Diameter Tolerance (mm) | |

| 1*2 | 0.15~0.30 | +0.03/-0 |

| 1*3 | 0.20~0.45 0.45~0.60 | +0.03/-0 +0.06/-0 |

| 1*7 | 0.18~0.45 0.45~0.70 0.70~1.20 | +0.03/-0 +0.06/-0 +0.10/-0 |

MECHANICAL PROPERTISE

| Alloy Code | UTS σ_b Mpa | Elongation δ% | UPS σ_load Mpa | Permanent Set After 6% Strain % | Active A_f °C |

| A | >=950 | >=10 | >=350 | <0.5 | 5±7° C TO 25±7° C |

NOTE :- All Mechanical Testing Conducted at 22°C +/- 2°C

Surface condition

Black surface oxidation

Light oxidation (golden to brown)

निटिनोल रोप (ट्विस्टेड) वायर, Nitinol-Seil (gedrehter) Draht, ニチノール ロープ(ツイステッド)ワイヤー, Nitinol Halat (bükülmüş) Tel,نٹینول رسی (مڑا ہوا) تار, Fil de Nitinol (torsadé), سلك نيتينول (ملفوف), নিটিনল দড়ি (পেঁচানো) তার, Нитинол канат (скрученный) провод, Cabo de Nitinol (torcido), Nitinol touw (gedraaide) draad, Nitinolrep (tvinnad) tråd, நிடினோல் கயிறு (திரிக்கப்பட்ட) கம்பி, Dây Nitinol (xoắn) dây dẫn, Filo di Nitinol (attorcigliato)