Nitinol wire is widely used in medical devices, aerospace components, robotics, and industrial applications due to its high strength, lightweight nature, and biocompatibility. Medical-grade Nitinol wire is commonly found in stents, guidewires, and orthodontic archwires, while industrial applications use it in smart actuators, sensors, and adaptive structures.

With its ability to withstand high strain levels without permanent deformation, Nitinol wire has revolutionized industries that require materials with high fatigue resistance and flexibility.

Our Expertise:

SMA WIRES INDIA is a leading manufacturer of custom Nitinol wire, offering solutions tailored to specific applications.

Custom Product Development:

🔹 Custom diameters & mechanical properties

🔹 Precision cutting & shape setting

🔹 Prototype Development & Mass Production

Applications:

🔹 Medical Devices – Stents, guidewires, dental arch wires, etc.

🔹 Aerospace & Defense – Smart actuators and morphing structures

🔹 Robotics & Automation – Shape memory actuators

Diameter and Tolerances

| Diameter (mm) | Tolerances (mm) |

| 4.000-2.000mm | ±0.020mm |

| 2.000-1.000mm | ±0.020mm |

| 1.000-0.350mm | ±0.012mm |

| 0.350-0.260mm | ±0.009mm |

| 0.260-0.150mm | ±0.008mm |

| 0.150-0.080mm | ±0.007mm |

| 0.080-0.050mm | ±0.005mm |

| 0.050-0.013mm | ±0.002mm |

| 0.013–0.090mm | ±0.002mm |

| 0-090–0.010mm | ±0.002mm |

NOTE :- Tighter Tolerance Available On Request.

Mechanical Properties

| Alloy code | UTS σ_b Mpa | Elongation δ% | UPS σ_load Mpa | Permanent Set After 6% Strain % | Active A_f °C |

| A | >=1300 | >=10 | >=480 | <0.5 | 10±7° C |

| B | >=1150 | >=10 | >=440 | <0.5 | 17±7° C |

| C | >=1000 | >=10 | >=400 | <0.5 | 25±5° C |

| D | >=950 | >=10 | >=300 | <0.5 | 35±5° C |

| E | >=550 | >=15 | >=200 | <0.5 | 35±8° C TO 110±8° C |

NOTE :- All Mechanical Testing Conducted at 22°C +/- 2°C

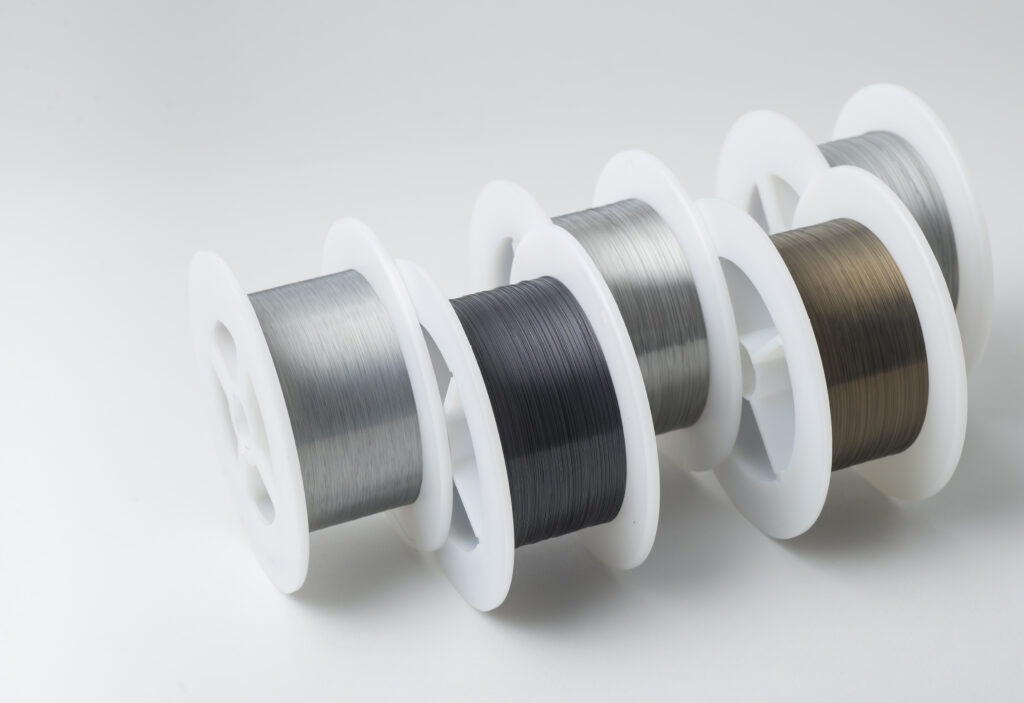

Surface condition

- Black surface oxidation

- Light oxidation (golden to brown)

- Etched surface

- Electropolishing surface (EP)

- Grinding surface

निटिनॉल वायर, Nitinol-Draht, ニチノールワイヤー, Nitinol Tel, نٹینول وائر, Fil de Nitinol, سلك نيتينول, নাইটিনল তার, Нитиноловая проволока, Fio de Nitinol, Nitinoldraad, Nitinoltråd, நிட்டினால் கம்பி, Dây Nitinol, Filo di Nitinol