About Us

SMA is a Manufacturer of a Shape Memory Alloys.

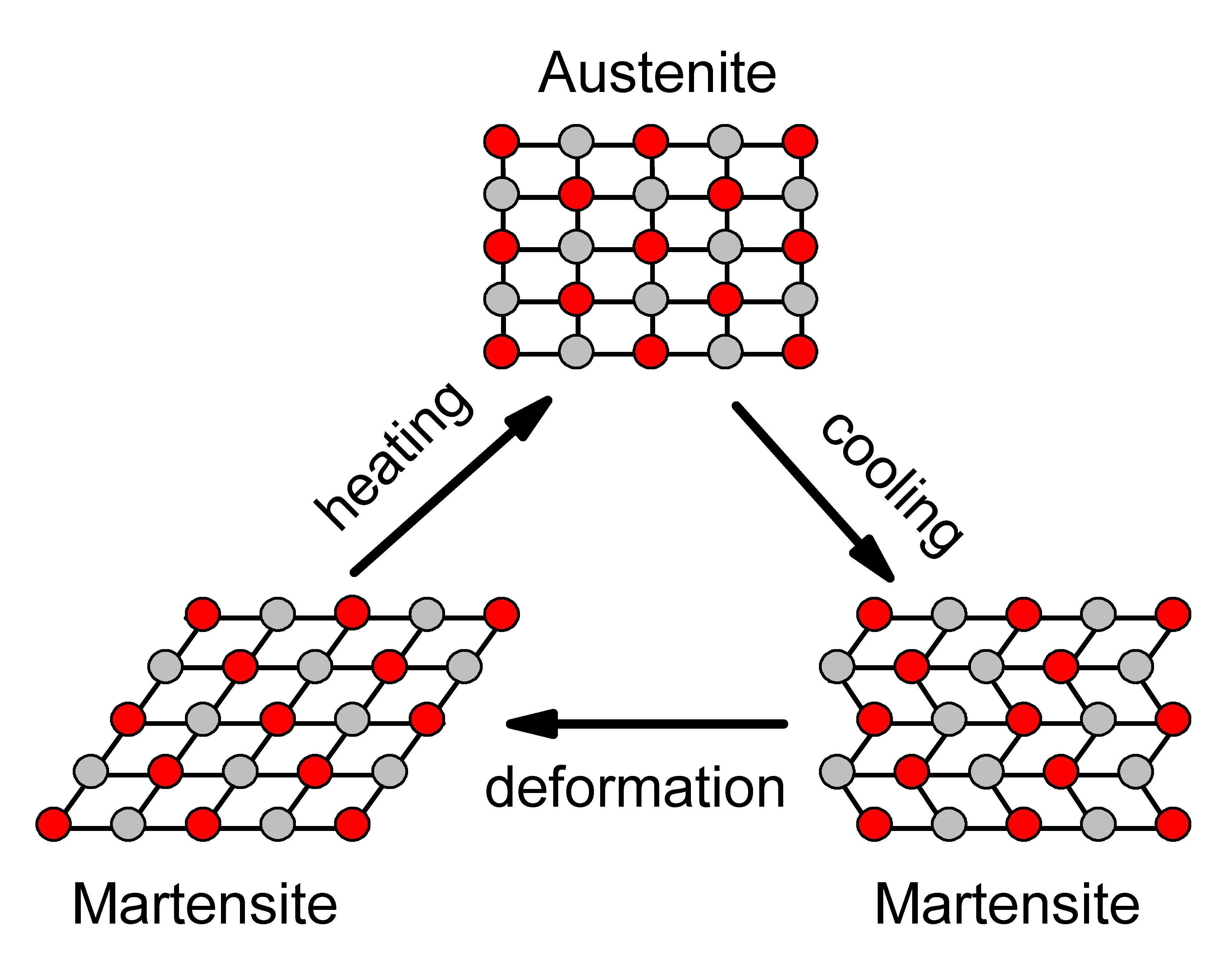

Contact usA shape memory alloy(SMA, smart metal, memory metal, memory alloy, muscle wire, Nitinol,smart alloy) is an alloy that "remembers" its original, coldâforged shape: returning the preâdeformed shape by heating. This material is a lightweight, solidâstate alternative to conventional actuators such as hydraulic, pneumatic, and motorâbased systems. Shape memory alloys have applications in industries including medical and aerospace.These are known as characteristic transformation temperatures. These temperatures are: Mfâmartensite finish; Msâmartensite start; Asâaustenite start; and Afâaustenitefinish.

TypesOf SMAâs:

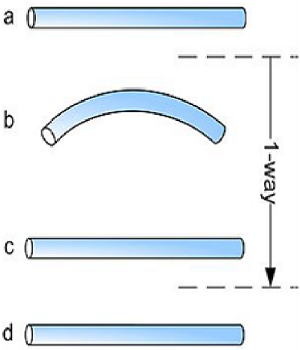

One way SMA :

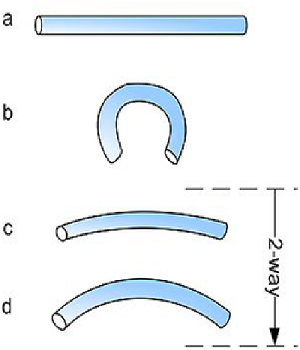

Two way SMA :

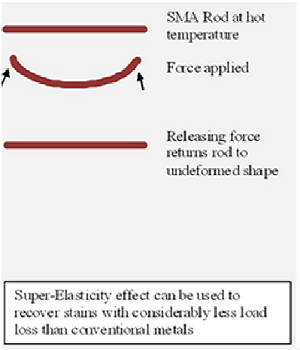

Super-Elasticity SMA:

One way memory effect

When a shape memory alloy is in its cold state (below As), the metal can be bent or stretched and will hold this shape until heated above the transition temperature.

- Upon heating, the shape changes to its original.

- When the metal cools again, it will remain in the hot shape until deformed again.

- In this case, cooling from high temperature does not cause macroscopic shape change.

Two way memory effect

This is the effect that the material remembers two shapes: one at high temp and the other at low temperature.- These metals show shape memory effect during both cooling and heating.

- The metal can be trained to leave some reminders of the deformed low temp condition in the high temp phases.

- IAbove a certain temp, the metal loses the 2 way memory effect. This is called âamnesiaâ.

SUPERâElasticity

- One of the commercial uses of shape memory alloy involves using the superâelastic properties of the metal during the high temperature (austenitic) phase. The frames of reading glasses have been made of shape memory alloy as they can undergo large deformations in their high temperature state and then instantly revert back to their original shape when the stress is removed. This is the result of super-elasticity; the martensitic phase is generated by stressing the metal in the austenitic state and this martensite phase is capable of large strains. With the removal of the load, the martensite transforms back into the austenite phase and resumes its original shape.

This allows the metal to be bent, twisted and pulled, before reforming its shape when released. This means the frames of shape memory alloy glasses are claimed to be "nearly indestructible" because it appears no amount of bending results in permanent plastic deformation.